Speak to a Steel Expert

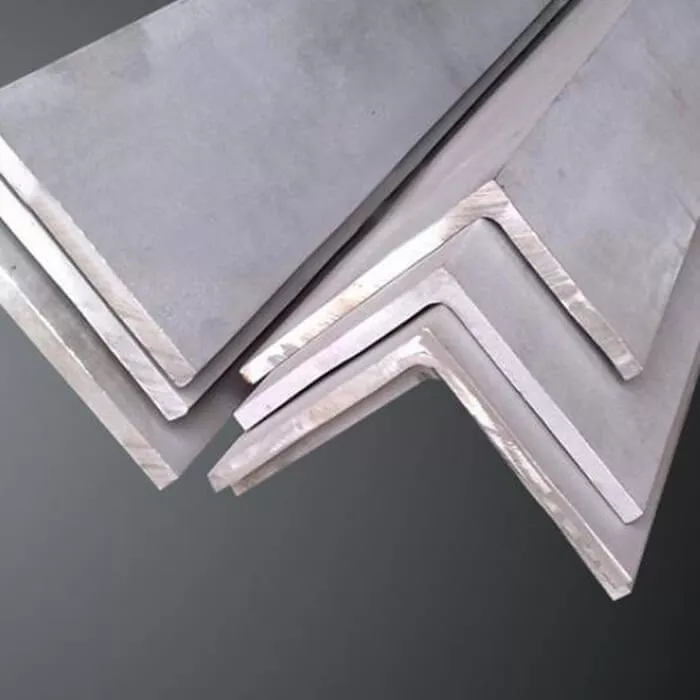

Galvanized angle steel

70x70x4 Hot dip Galvanized equal steel angle

Gi Angle bar hot-dip 50x50x4 90 degree steel dealer

ASTM A36 Angle Profiles

Unequal Angle Steel

ASTM ss400 Gi steel angle perforated with holes

30x30x3mm Hot-rolled Steel Gi Steel Angle dealer

3x5 5 inch 2.5 angle 180x180 Gi angle steel dealer

Galvanized L shaped Angle Steel

ASTM 6mm thick hot dip Slotted Galvanized Angle Dealer

Hot rolled Galvanized Angle Steel with hole Dealer

Galvanized angle steel profile for building Dealer

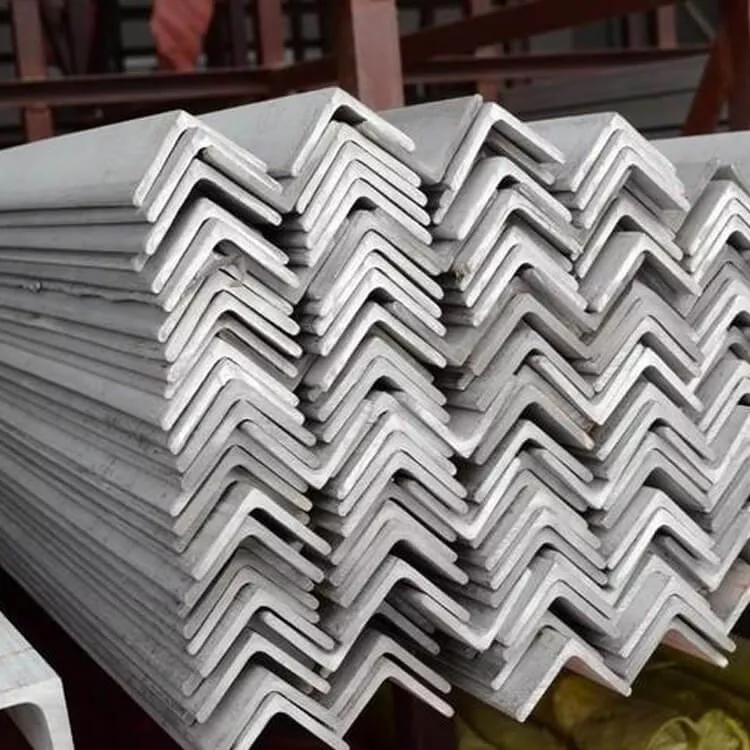

Hot rolled galvanized steel angle manufacturer

Hot dipped gi steel angle wall angle 3mm thick dealer

50x50 A36 galvanized steel angle manufacturer

2 inch hot dipped galvanized angle steel dealer