2021-12-30

In the regular trading of galvanized sheets, cold-rolled basic galvanization is the main one, and hot-rolled substrates are relatively rare. Then, what is the difference between hot-rolled substrates and cold-rolled substrates galvanized products? Let's make a simple interpretation from the following aspects:

1. Cost

Because there is one less process than cold-rolled substrates, hot-rolled substrate galvanizing is cheaper than cold-rolled production costs, mainly due to annealing costs and cold-rolling costs, and the other processes are similar.

2. Quality performance

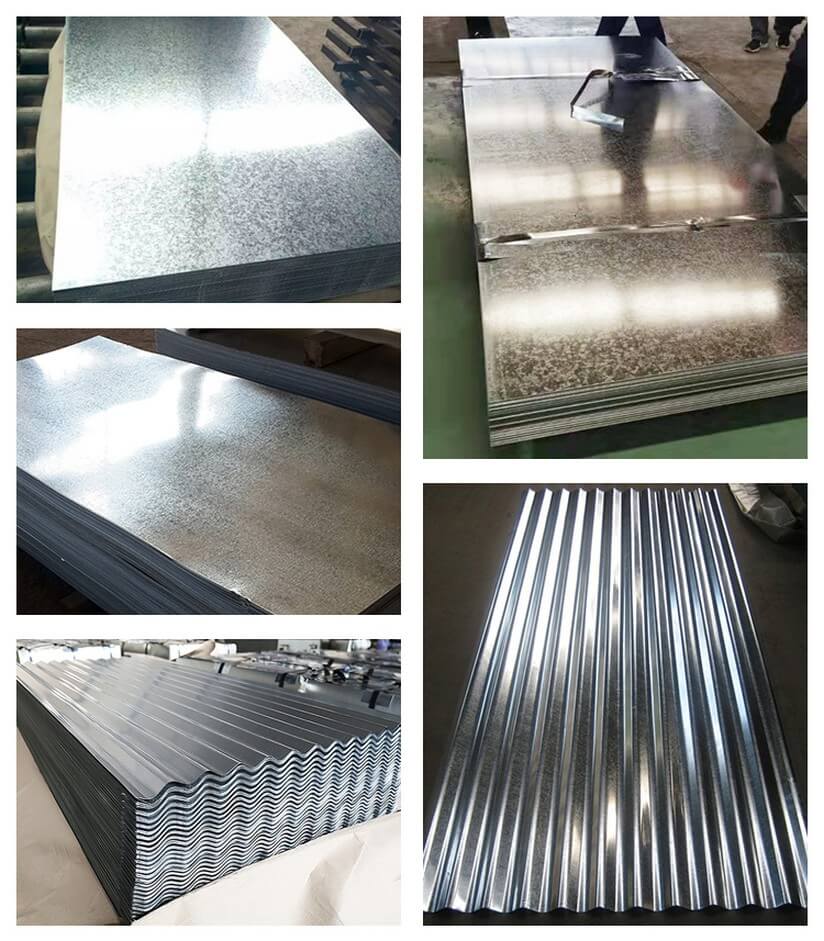

Because the hot-rolled substrate is only pickled and annealed to remove surface impurities, its surface is relatively rough, the adhesion of the zinc layer is better, and the thickness of the coating is biased towards 140/140g/m2. However, the thickness dimension is not as high as that of cold rolling. Since most of the zinc layers are thick, the thickness of the zinc layer is not uniformly controlled. There is little difference in mechanical properties, and some properties are even better than cold rolling.

3. Application areas

Hot-rolled base plate galvanized sheet is not as good as cold-rolled base plate because of its dimensional accuracy and surface quality, and the thickness is thicker than cold-rolled galvanized sheet, so it is often used for structural members with low surface requirements but high strength and thickness requirements.

For example, the structural parts of washing machines, refrigerators and other household appliances, automobile internal structural parts, automobile chassis structural parts, passenger car body, roof, highway guardrail, cold-formed steel, etc.

Because the cost of hot-rolled galvanized sheet is low, and with the progress of the technology, the thickness of the specifications has become larger and larger, and the amount of use has gradually increased.