Speak to a Steel Expert

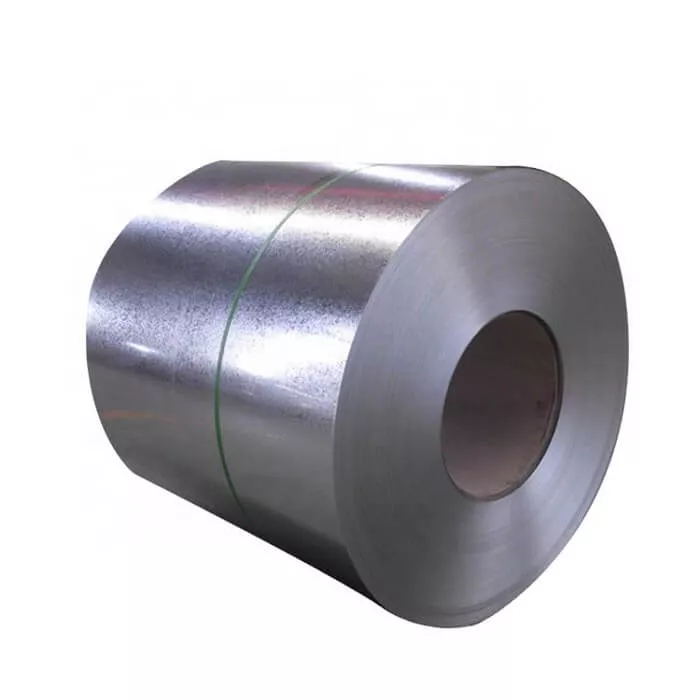

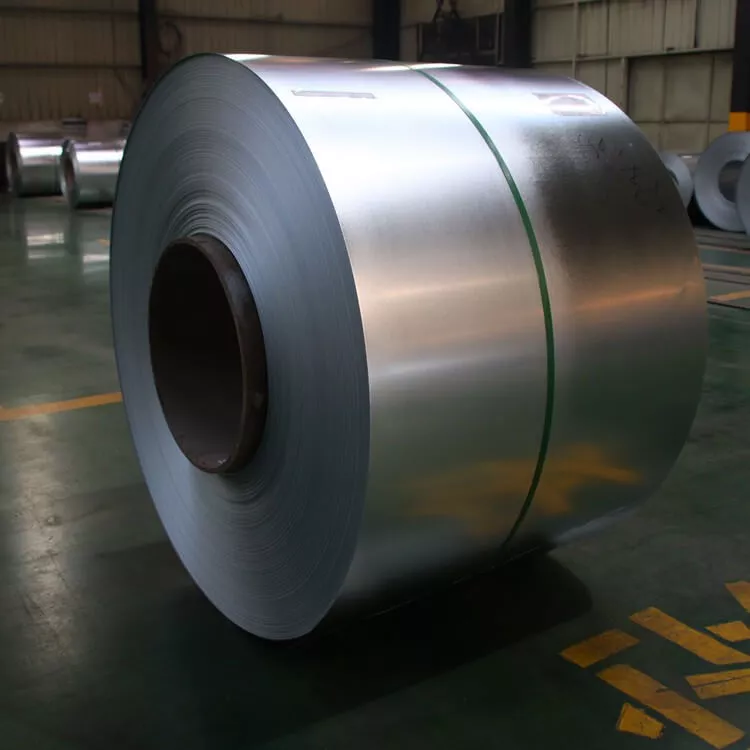

Galvanized steel coil

Dx51d sgcc Gi Steel coil

0.8-1.3mm Prepainted Gi Steel Coil|Gi Cold Rolled Ring Coil

Galvanized Steel Coil Cgi|Gi Coil For Construction dealer

Double Side Gi Steel Coil|Gi Coil 08f Polyester dealer

Hot-Dip Galvanized Sheet Metal Roll|Jisg3302 Gi Steel Coil

Gi Zinc Coating Steel Coil|Sgcc Gi Coil Zero Spangle dealer

Gi Coil For Corrugated Roofing Sheet

Z60 Galvanized Coil Open Type|Gi Coil For Roofing Tile

Galvanized Coil For Roofing Tile|Z275 Gi Coil Open Type

Matt Galvanized Steel Coil|2mm S275gd Hot Dipped Gi Coil

Sph440 Galvanized Coil|G450 Zinc Coated GI Steel Coil

Galvanized Steel Coil|G60 Z100 Cold Rolled Galvanized Coil

Hot Dipped Dx52d Z275 Galvanized Steel Coil manufacturer

0.35mm Dx51d Galvanized Steel Coil For Roofing Sheets

Galvanized Coils|Dx51d Z100 Galvanized Steel Coils