Speak to a Steel Expert

Galvanized Steel Pipe

1 inch galvanized pipe,3 inch galvanized STEEL pipe

2 inch galvanized pipe

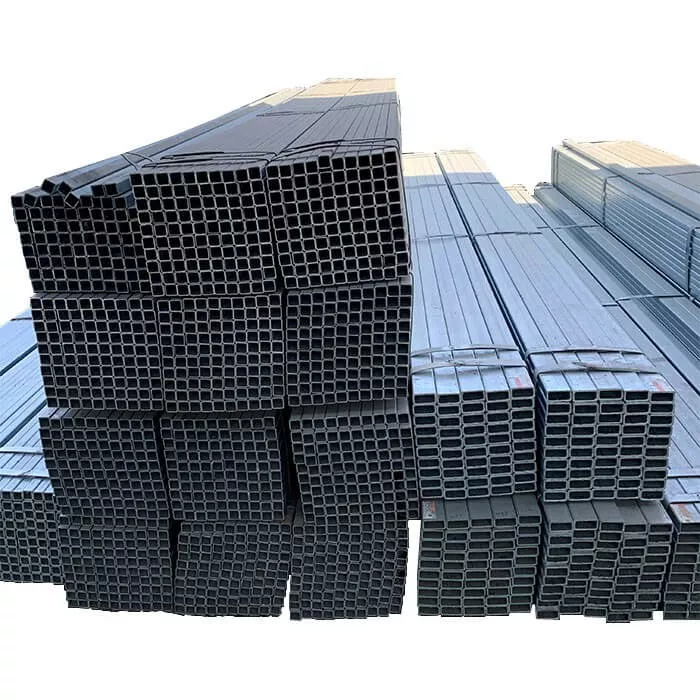

ASTM A36 Gi square steel pipe Tube manufacturer

3" Gi square steel pipe

Gi Square Tube Manufacturer

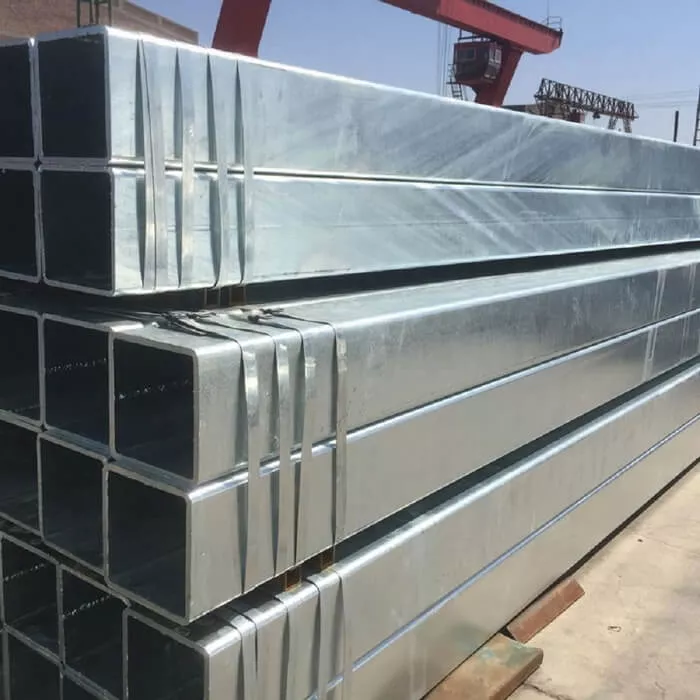

ASTM A53 Square Tube Rectangular Tube

Agricultural galvanized pipe

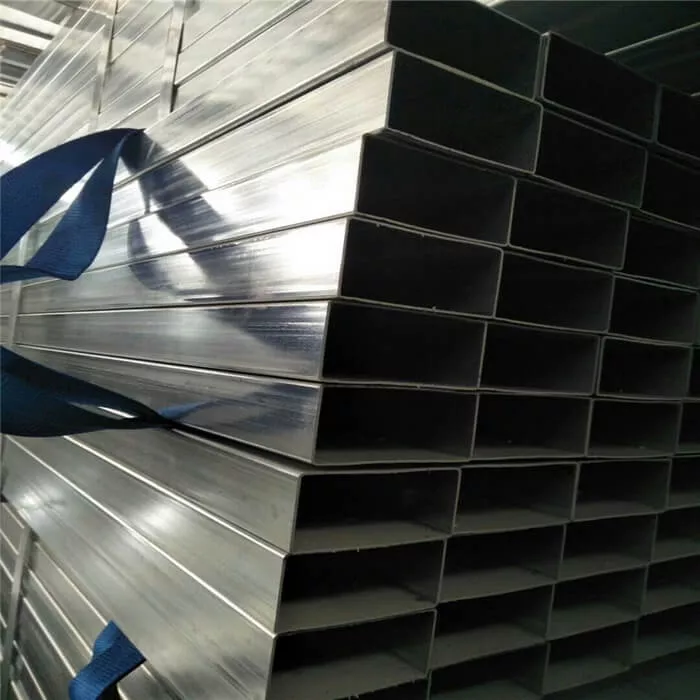

Hot dip Galvanized square tube

76mm Galvanized Teel Tube

Hot Dip Galvanized Tube manufacturer

Hot Dipped Galvanized Steel Pipe|48.3mm Gi Steel Pipe

2 square galvanized steel tube

3x3 galvanized square tube

6" galvanized steel pipe

Perforated square tube