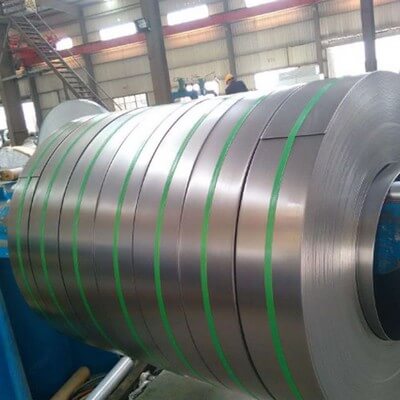

Cold Rolled Coil CR Bright Annealed SPCC SPCD

Cold-rolled coil: Using hot-rolled steel coil as raw material, after pickling to remove oxide scale, cold rolling is carried out.

Continuous rolling, the finished product is a cold-rolled coil. Due to the cold work hardening caused by continuous cold deformation, the strength, hardness and toughness and plastic index of the hard-rolled coil increase, so the stamping performance will deteriorate, and it can only be used for simple deformed parts. Cold-rolled coils can be used as raw materials for hot-dip galvanizing plants, because hot-dip galvanizing lines are equipped with annealing lines. The weight of rolled hard coil is generally 6~13.5 tons.

1. Uniform thickness:

Cold rolled sheet and coil are of uniform size and thickness, which can fully meet the requirements of high-precision public service.

2. Strip thickness:

The extremely thin strip that cannot be produced by hot rolling can be obtained, and the thickness can be less than 0.001 mm.

3. Superior quality:

The appearance quality of cold-rolled products is superior, and there are no defects such as pitting, pressed iron oxide scale and so on that often appear in hot-rolled coils. In addition, the coils with different appearance roughness can be produced according to the user's request, so as to facilitate the processing of the next process.

4. High strength:

The coil length of cold rolled sheet has excellent mechanical and technological functions, high strength, low compliance limit, excellent deep drawing function, etc.

5. High production rate:

It can complete high-speed rolling and full continuous rolling with high yield.

JIS G3141 SPCC Cold Rolled Coil

| C | Mn | P | S |

| ≤0.15 | ≤0.60 | ≤0.100 | ≤0.050 |

| Yield Strength Mpa | Tensile Strength Mpa | Elongation(Thickness) | |

| 140~280 | ≧270 | 0.25-2.5mm | ≥2.5mm |

| ≧34 | ≧34 | ||

JIS G3141 SPCD Cold Rolled Coil

| C | Mn | P | S |

| ≤0.12 | ≤0.50 | ≤0.04 | ≤0.040 |

| Yield Strength Mpa | Tensile Strength Mpa | Elongation(Thickness) | |

| 240 | ≧270 | 0.25-2.5mm | ≥2.5mm |

| 30-40 | ≧41 | ||

JIS G3141 SPCE Cold Rolled Coil

| C | Mn | P | S |

| ≤0.15 | ≤0.45 | ≤0.030 | ≤0.030 |

| Yield Strength Mpa | Tensile Strength Mpa | Elongation(Thickness) | |

| 220 | ≧270 | 0.25-2.5mm | ≥2.5mm |

| 32-42 | ≧43 | ||

JIS G3141 SPCF Cold Rolled Coil

| C | Mn | P | S |

| ≤0.08 | ≤0.45 | ≤0.030 | ≤0.030 |

| Yield Strength Mpa | Tensile Strength Mpa | Elongation(Thickness) | |

| ≤220 | ≥270 | 0.25-2.5mm | ≥2.5mm |

| ≧40 | ≧45 | ||

JIS G3141 SPCG Cold Rolled Coil

| C | Mn | P | S |

| ≤0.02 | ≤0.25 | ≤0.020 | ≤0.020 |

| Yield Strength Mpa | Tensile Strength Mpa | Elongation(Thickness) | |

| ≤210 | ≧270 | 0.25-2.5mm | ≥2.5mm |

| ≧40 | ≧45 | ||

EN 10130-DC01 Cold Rolled Coil

| C | P | S | Mn | Ti |

| ≤0.12 | ≤0.045 | ≤0.100 | ≤0.60 | - |

| Yield Strength Mpa | Tensile Strength Mpa | Elongation(Thickness) | ||

| 140-280 | 270-410 | ≥28 | ||

EN 10130-DC03 Cold Rolled Coil

| C | P | S | Mn | Ti |

| ≤0.10 | ≤0.035 | ≤0.035 | ≤0.45 | - |

| Yield Strength Mpa | Tensile Strength Mpa | Elongation(Thickness) | ||

| 140-240 | 270-370 | ≥38 | ||

EN 10130-DC04 Cold Rolled Coil

| C | P | S | Mn | Ti |

| ≤0.08 | ≤0.030 | ≤0.030 | ≤0.40 | - |

| Yield Strength Mpa | Tensile Strength Mpa | Elongation(Thickness) | ||

| 140-210 | 270-350 | ≥38 | ||

EN 10130-DC05 Cold Rolled Coil

| C | P | S | Mn | Ti |

| ≤0.06 | ≤0.025 | ≤0.0250 | ≤0.35 | - |

| Yield Strength Mpa | Tensile Strength Mpa | Elongation(Thickness) | ||

| 140-180 | 270-330 | ≥40 | ||

EN 10130-DC06 Cold Rolled Coil

| C | P | S | Mn | Ti |

| ≤0.020 | ≤0.020 | ≤0.020 | ≤0.25 | 0.3 |

| Yield Strength Mpa | Tensile Strength Mpa | Elongation(Thickness) | ||

| 120-170 | 270-330 | ≥41 | ||

EN 10130-DC07 Cold Rolled Coil

| C | P | S | Mn | Ti |

| ≤0.010 | ≤0.020 | ≤0.020 | ≤0.20 | 0.2 |

| Yield Strength Mpa | Tensile Strength Mpa | Elongation(Thickness) | ||

| 100-150 | 250-310 | ≥44 | ||

| Product | Cold Rolled Steel coil |

| Thickness | 0.7-9mm |

| Width | 40mm to 400mm |

| Length | as per your requirement |

| Grade | SAE 1043, SAE 1046, 45Mn, S45C, BS108A47 |

| Standard | GB,JIS,DIN,AISI,ASTM |

| Material | 40Mn,45Mn,50#,65Mn,Sk5,Q235,Q195,20Mn,30CrMo,40CrMo,42CrMo.. |

| Technology | Cold rolled |

| Payment terms | T/T, 30% as deposit and 70% before shipment. |

| Delivery time | Within 20-30 days after deposit |

| Package | In bundle/coil, seaworthy package or as requested |

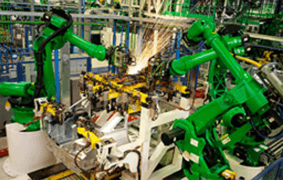

Shandong Kuaima Steel Co., Ltd. has advanced special smelting, investment casting, pipe making and other production equipment. The company has 15 advanced production lines, which can independently produce hot/cold rolled steel, galvalume steel, galvanized steel, prepainted steel and stainless steel coils, strips, plates, plates, pipes, bars and other products. The standing inventory is more than 450,000 tons to meet the customer's demand for delivery time.

| cold rolled carbon steel steel strip coils | carbon steel coil/plate factories |

| cold rolled carbon steel coil factories | carbon steel coil/plate |

| cold reduced carbon steel coil | carbon steel coil wholesaler |

| china carbon steel coil | carbon steel coil supplier |

| cheap cold rolled carbon steel coil | carbon steel coil strip in stock |

| carbon steel cold rolled coil | astm a36 coil carbon steel |

| carbon steel coils quotes | alloy carbon steel coil |

| carbon steel coils factory | cold rolled carbon steel coil |

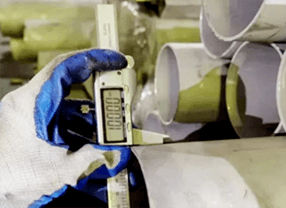

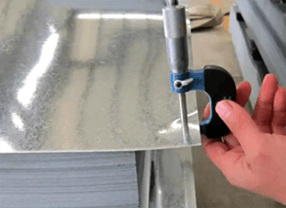

We have professional testing equipment. We have our own testing center laboratory to guarantee the quality of our products.

thickness

width

coating quality

chromatic aberration

paint

thickness

hardness

luster

tensile strength

Yield Strength

We are a world-renowned Cold rolled steel coil and sheet exporter, Qatar, Ireland, Portugal,Gambia, Thailand, Ukraine, United Kingdom, Netherlands, South Africa, Spain, Turkey, Italy, Libya, Ro-Fanaticism, Puerto Rico, Azerbaijan, United Arab Emirates, Pakistan, Philippines, Ghana, Slovakia, Germany,Saudi Arabia, Afghanistan, China, Bolivia, Switzerland, Bangladesh, Taiwan, Oman, Egypt, Greece,Norway, Singapore, Bulgaria, Estonia, Belgium, Yemen, Hong Kong, Ecuador, Sri Lanka, Nepal, Belarus,Finland, Gabon, Iran, Canada, Argentina, Lebanon. other countries

Speak to a Steel Expert