PPGi Ral 9028 Building Material Matte Steel Coil dealer

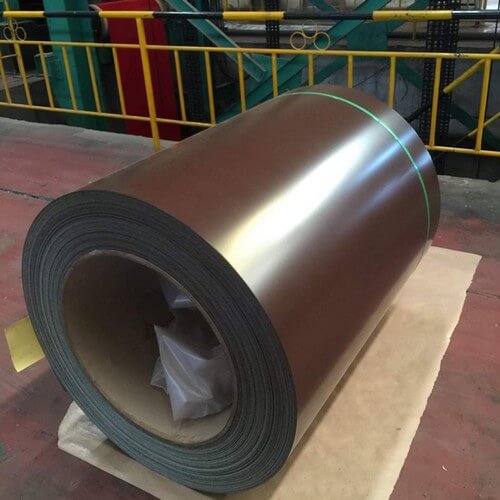

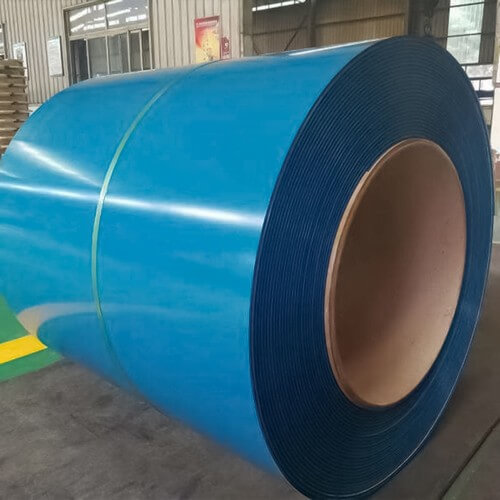

Aluminized zinc color plate is a chemical conversion treatment on the surface of aluminized zinc (55%A1-43.5%Zn-1.5%Si) substrate, and then a special primer treatment (5um), and finally coating according to user needs It is a color-coated product obtained by applying a layer of about 20μm of various paints of different colors with excellent processability and durability. This product is widely used on the walls and roofs of buildings.

Products made from pre-painted metal offers a top-quality painted surface. There is a broad spectrum of textures and colors. You can also give special effects like woodgrain by considering printed films. The pre-painted metal surface can be extremely mat or smooth, embossed, orange-peel, or high gloss.

A pre-painted metal is available in the typical aluminum and steel alloys and grades, so you can ensure a balanced strength, appearance, and formability in your final product.

It is also a great choice for those looking for a sustainable design. Several pieces of research have concluded that it has less environmental impact as compared to the post-painted metals across an array of impact classifications. It is also very convenient to recycle pre-painted metals.

Coil coatings use organic coatings that are normally thinner as compared to the post-applied films and powders. However, they still offer improved in-service performance. Therefore, you will be using less paint, minimizing resource consumption. It allows you to eliminate or cut down re-painting and maintenance.

The continuous process of coil coating ensures the highest quality assurance standards via coil-to-coil consistency. Also, the environmental emissions are also lower than post-painting or batch processes.

The processes of coil coating are run according to the latest VOC emissions standards. Thus, this makes it the best choice for a broad spectrum of applications. Therefore, the pre-coated coils are great solutions in terms of design.

Pre-painted metals have extensive use in the production of domestic appliances. Moreover, it saves a lot of money for domestic appliance manufacturers.

Pre-painted coils make the manufacturing process run more consistently and smoother that ultimately helps them save money. There are improvements in the yield and productivity alongside a reduction in the cost of manufacturing, inventory, financial, and energy.

Manufacturers also eliminate paint lines by using the pre-painted coils in the process. Paint lines are the main hurdles in the operation. They are also able to minimize capacity constraints that potentially improve the ROCE.

One production advantage of the pre-painted coil is that it reduces the costs linked with meeting environmental regulations. Eradicate, the Hazardous waste disposal cost that is usually a part of the painting process.

Processing costs of batch-type are also removed or minimized alongside the removal of the scheduling problems. Since there is a direct relation between the input material and output, there is a decrease in the processing time. Another important advantage is the minimized stocks.

A color coated coil has a consistent quality and it minimizes the re-work need. It also reduces the levels of non-conformance as well as the associated costs. The biggest benefit of using pre-painted sheets is that they allow you to pay focus on your core competencies while leaving the paint finishes production to experts.

Steel Grade | DC51D+Z, DC52D+Z, DC53D+Z, S280GD+Z, S350GD+Z, S550GD+Z, DC51D+AZ, DC52D+AZ, S250GD+AZ, S300GD+AZ, S350GD+AZ, S550GD+AZ, SECC, SECE, BLCE+Z, BLDE+Z, BUSDE+Z |

Base Steel | Hot dip galvanized steel, Hot dip galvalume steel, Electro galvanized steel |

Thickness | 0.12-3.0mm |

Width | 600-1000mm |

Surface Color | RAL,wood grain pattern, camouflage pattern , stone pattern, matte pattern , high gloss pattern , flower pattern, etc |

Quality | Approved by SGS,ISO |

Coil Weight | 3-20metric ton per coil |

Water proof paper is inner packing,galvanized steel or coated steel sheet is outer packing , side guard plate,then wrapped by | |

Export market | Europe,Africa,Central Asia,Southeast Asia,Middle East,South America,North America, etc |

Coil Weight | 3-8 Tons |

Spangle | Zero.minimum .Regular Big Spangle |

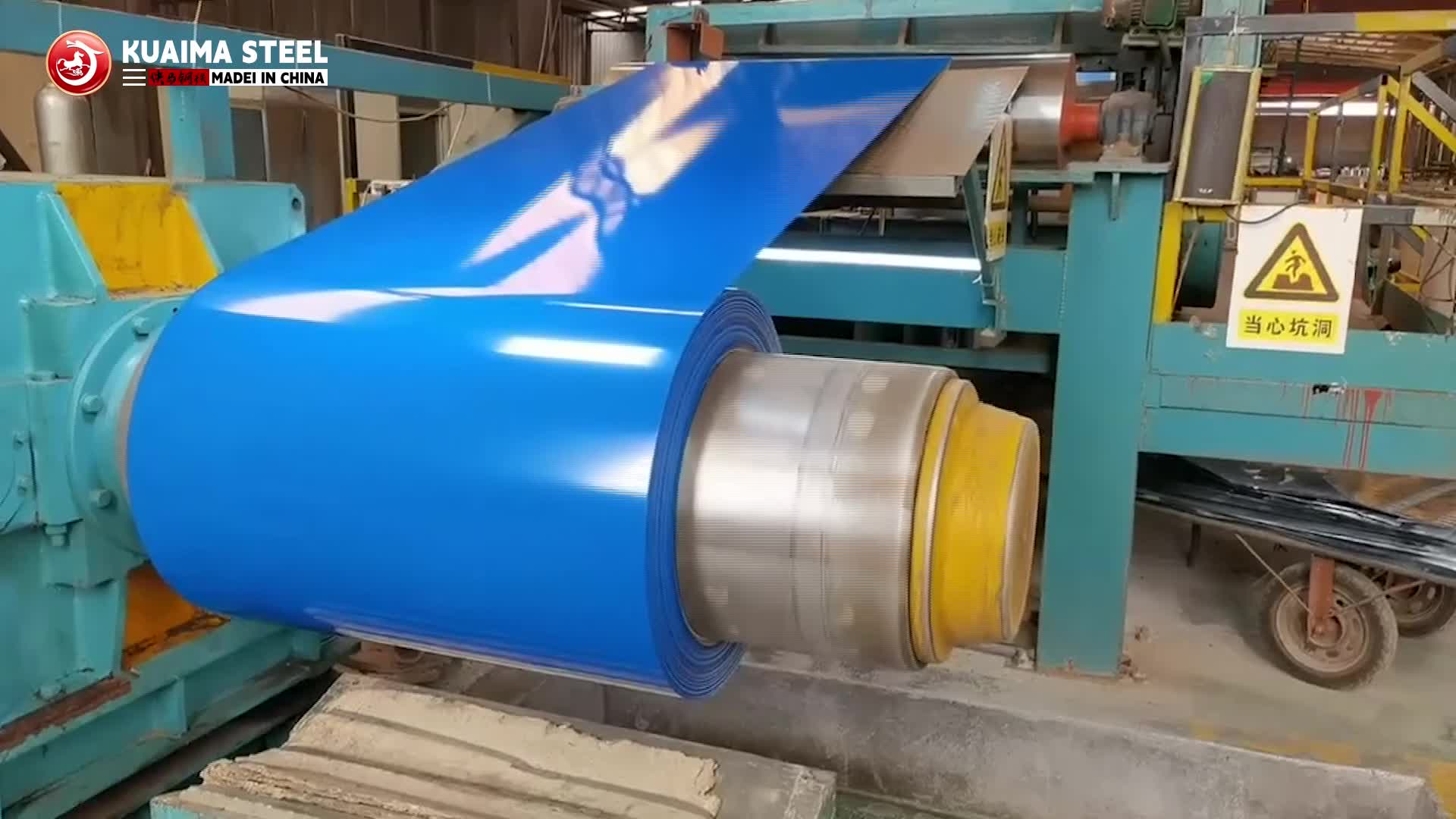

Shandong Kuaima Steel Co., Ltd. has advanced special smelting, investment casting, pipe making and other production equipment. The company has 15 advanced production lines, which can independently produce PPGI/color coated galvanized steel coil hot/cold rolled steel, galvanized steel, galvanized steel, prepainted steel and stainless steel coils, strips, plates, plates, pipes, bars and other products. The standing inventory is more than 450,000 tons to meet the customer's demand for delivery time.

| china ppgi colour coated sheet manufacturer | china ppgi sheet full form factories |

| china ppgi corrugated sheet | china ppgi sheet rate manufacturers |

| china ppgi corrugated sheet manufacturer | china ppgi sheet suppliers |

| china ppgi corrugated sheet supplier | china ppgi sheet thickness supplier |

| china ppgi factories | china ppgi sheet weight factory |

| china ppgi factory | china ppgi sheets factories |

| china ppgi full form | china ppgi specifications factories |

| china ppgi full form supplier | china ppgi steel |

We have professional testing equipment. We have our own testing center laboratory to guarantee the quality of our products.

thickness

width

coating quality

chromatic aberration

paint

thickness

hardness

luster

tensile strength

Yield Strength

We are a world-renowned PPGI/prepainted galvanized steel coil exporter, Qatar, Ireland, Portugal,

Gambia, Thailand, Ukraine, United Kingdom, Netherlands, South Africa, Spain, Turkey, Italy, Libya, Ro-

Fanaticism, Puerto Rico, Azerbaijan, United Arab Emirates, Pakistan, Philippines, Ghana, Slovakia, Germany,

Saudi Arabia, Afghanistan, China, Bolivia, Switzerland, Bangladesh, Taiwan, Oman, Egypt, Greece,

Norway, Singapore, Bulgaria, Estonia, Belgium, Yemen, Hong Kong, Ecuador, Sri Lanka, Nepal, Belarus,

Finland, Gabon, Iran, Canada, Argentina, Lebanon. other countries

Speak to a Steel Expert