Ppgi Dx51 galvanized cold rolled sheet description

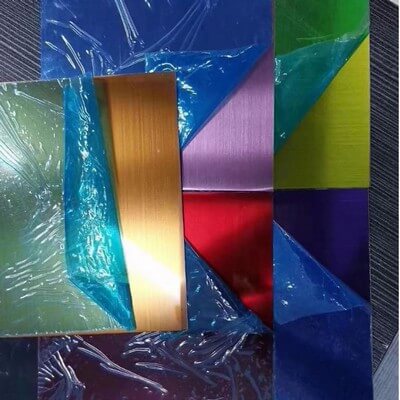

Color coated steel plate is a kind of composite metal plate, also known as "color organic coated steel plate", which is coated with various protective and decorative coatings after surface treatment with galvanized steel plate or cold rolled steel plate as the base. Color coated steel plate from the inside to the outside of the structural layer is cold rolled, galvanized layer, chemical conversion layer, primary coating (primer), fine coating (front and back paint). This plate surface color novel, strong adhesion, corrosion resistance and decorative, and good processing performance, can be shear, bending, drilling, riveting, crimping and so on. Commonly used coating is divided into inorganic coating, organic coating and composite coating three categories.

Color coated steel plate is mainly used as building exterior wall panel, directly used to form the wall is required to do the insulation layer; In addition, it can also be used for roofing board, corrugated board, waterproof and gas permeable board, corrosion resistant equipment and components, furniture, car shell, water baffle and so on.

| Name | PPGL Roof Tile SGCC Building Material G90 Prepainted Ral Color Coated Galvanized Metal Roof Tiles Gi Metal Steel PPGI Colour Coating Corrugated Roofing Sheet | |

| Thickness | 0.12mm-1.2mm | |

| Width | 660-1150mm | |

| Paint | Top Paint:10-25 micron/Back paint: 5-12 micron | |

| Coating | Zn coating | AZ coating |

| 30-275gsm | 30-275gsm | |

| Grade | Galvanized | Galvalume |

| DX51D+Z, DX52D+Z, DX53D+Z, DX54D+Z, DX56D+Z, DX57D+Z, DC51D+Z, SGCC, SGCD, S220GD+Z, S250GD+Z, S350GD+Z, S550GD+Z | SGLCC,SGLCD,ASTMA792,ASTMA755DX51D+AZ,DX52D+AZ,DX53D+AZ, DX54D+AZ,S250GD+AZ,S280GD+AZ, S320GD+AZ,S350GD+AZ,S550GD+AZ | |

| Coating type | Top paint: PE, SMP, HDP, PVDF, PU | |

| Primer paint: Polyurethane, Epoxy, PE | ||

| Back paint: Epoxy, Modified polyester | ||

| Finish | High light, Glossy, Matte | |

| Type of coating process | Front: Double coated & double drying | |

| Back: Double coated & double drying, single coated & double drying | ||

| Double coated & double drying is used for corrugated sheet | ||

| Double coated & single drying is for sandwich panel | ||

| Application | Building industry ,structural use, roofing, commercial use ,household appliance, industry facilities, office buildings | |

Shandong Kuaima Steel Co., Ltd. has advanced special smelting, investment casting, pipe making and other production equipment. The company has 15 advanced production lines, which can independently produce hot/cold rolled steel, Color coated steel roof panel,galvalume steel, galvanized steel, prepainted steel and stainless steel coils, strips, plates, plates, pipes, bars and other products. The standing inventory is more than 450,000 tons to meet the customer's demand for delivery time.

| ppgi plate | buy ppgi |

| ppgi sheet | wholesale ppgi steel plate |

| ppgi ppgl | ppgi roofing sheet |

| steel plate ppgi | ppgi sheet manufacturers |

| wholesale ppgi sheet | cheap ppgi factory |

| china ppgi steel sheet | excellent quality ppgi factory |

| ppgi plate factory | ppgi steel |

| ppgi sheet quotes | ppgi color coated sheets |

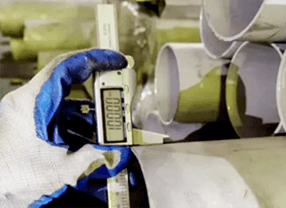

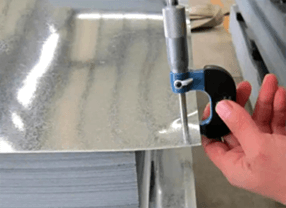

We have professional testing equipment. We have our own testing center laboratory to guarantee the quality of our products.

thickness

width

coating quality

chromatic aberration

paint

thickness

hardness

luster

tensile strength

Yield Strength

We are a world-renowned Color coated steel roof panel exporter, Qatar, Ireland, Portugal,Gambia, Thailand, Ukraine, United Kingdom, Netherlands, South Africa, Spain, Turkey, Italy, Libya, Ro-Fanaticism, Puerto Rico, Azerbaijan, United Arab Emirates, Pakistan, Philippines, Ghana, Slovakia, Germany,Saudi Arabia, Afghanistan, China, Bolivia, Switzerland, Bangladesh, Taiwan, Oman, Egypt, Greece,Norway, Singapore, Bulgaria, Estonia, Belgium, Yemen, Hong Kong, Ecuador, Sri Lanka, Nepal, Belarus,Finland, Gabon, Iran, Canada, Argentina, Lebanon. other countries

Speak to a Steel Expert