Brushed Color Coated 201 Stainless Steel Sheet Dealer

Color stainless steel plates are classified by surface effect: mirror plate (8K), brushed plate (LH), frosted plate, and pattern plate, sandblasted plate, etched plate, embossed plate, composite plate (combination plate).

1. Color stainless steel mirror panel

The 8K board, also known as the mirror board, is polished on the stainless steel surface with abrasive liquid through polishing equipment, so that the board surface brightness is as clear as a mirror, and then electroplated and colored.

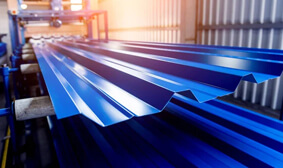

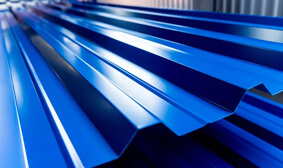

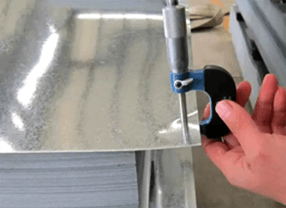

2. Color stainless steel wire drawing board

Pull wire (LH), also called hairline, because the lines are slender and straight like hair. Its surface is like a filamentous texture, which is a processing technology of stainless steel. The surface is matt, and there are traces of texture on it, but it can't be felt. It is more wear-resistant than ordinary bright stainless steel and looks more upscale. The hairline board has a variety of patterns, including hairline (HL), snowflake sand pattern (NO4), and pattern (chaotic pattern), cross pattern, cross pattern, etc. All patterns are processed by oil-throwing hairline machine as required. into, and then electroplating and coloring.

1. Easy to clean surface:

It is easy to clean the surface stains without metal cleaning agent. Some chemicals will make the surface of stainless steel black; It is not easy to paste fingerprints and dust, and has a delicate feel. It has a strong fingerprint and antifouling effect.

2. Prevent surface scratch:

The fingerprint-free transparent film can protect the metal surface from scratches, because the surface electroplated gold oil has good film performance, high hardness, not easy to peel off, chalking, yellowing and other characteristics, and has a solid, oily, moist, soft, tactile appearance, and maintains a good metal texture.

3. Enhance surface rust resistance:

The color stainless steel fingerprint-free plate has excellent anti-rust performance, forms a protective film on the metal surface, effectively prevents metal internal corrosion, and greatly extends the service life of the color stainless steel plate.

Type | Color Coating stainless steel sheets |

Thickness | 0.3 mm - 3.0 mm |

Size | 1000*2000mm, 1219*2438mm, 1219*3048mm, customized Max.width 1500mm |

SS Grade | 304,316, 201,430 etc. |

Finish | PVD Color Coating |

Avaible finishes | No.4, Hairline, Mirror, Etching, PVD Color, Embossed, Vibration, Sandblast, Combination, lamination etc. |

Origin | China |

Packing way | PVC+ waterproof paper + strong sea-worthy wooden package |

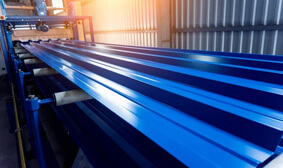

Shandong Kuaima Steel Co., Ltd. has advanced special smelting, investment casting, pipe making and other production equipment. The company has 15 advanced production lines, which can independently produce hot/cold rolled steel, galvalume steel, galvanized steel, prepainted steel and stainless steel coils, strips, plates, plates, pipes, bars and other products. The standing inventory is more than 450,000 tons to meet the customer's demand for delivery time.

| galvanized steel sheet coil | a653 galvanized steel sheet |

| galvanized steel sheet factory | china g550 galvanized steel coils sheets |

| hot-dip galvanized steel sheet | china galvanized steel sheet |

| galvanizing steel sheet | cost of galvanized steel sheets |

| galvanized steel sheet supplier | z60 z180 galvanized steel coil sheet |

| galvanized plain steel sheets | steel coils sheets galvanized |

| galvanized stainless steel sheets | galvanized steel sheet 20 gauge |

| galvanized steel metal sheets | galvanized steel sheet hot rolled |

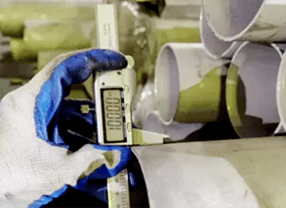

We have professional testing equipment. We have our own testing center laboratory to guarantee the quality of our products.

thickness

width

coating quality

chromatic aberration

paint

thickness

hardness

luster

tensile strength

Yield Strength

We are a world-renowned Color coated stainless steel plate exporter, Qatar, Ireland, Portugal,Gambia, Thailand, Ukraine, United Kingdom, Netherlands, South Africa, Spain, Turkey, Italy, Libya, Ro-Fanaticism, Puerto Rico, Azerbaijan, United Arab Emirates, Pakistan, Philippines, Ghana, Slovakia, Germany,Saudi Arabia, Afghanistan, China, Bolivia, Switzerland, Bangladesh, Taiwan, Oman, Egypt, Greece,Norway, Singapore, Bulgaria, Estonia, Belgium, Yemen, Hong Kong, Ecuador, Sri Lanka, Nepal, Belarus,Finland, Gabon, Iran, Canada, Argentina, Lebanon. other countries

Speak to a Steel Expert