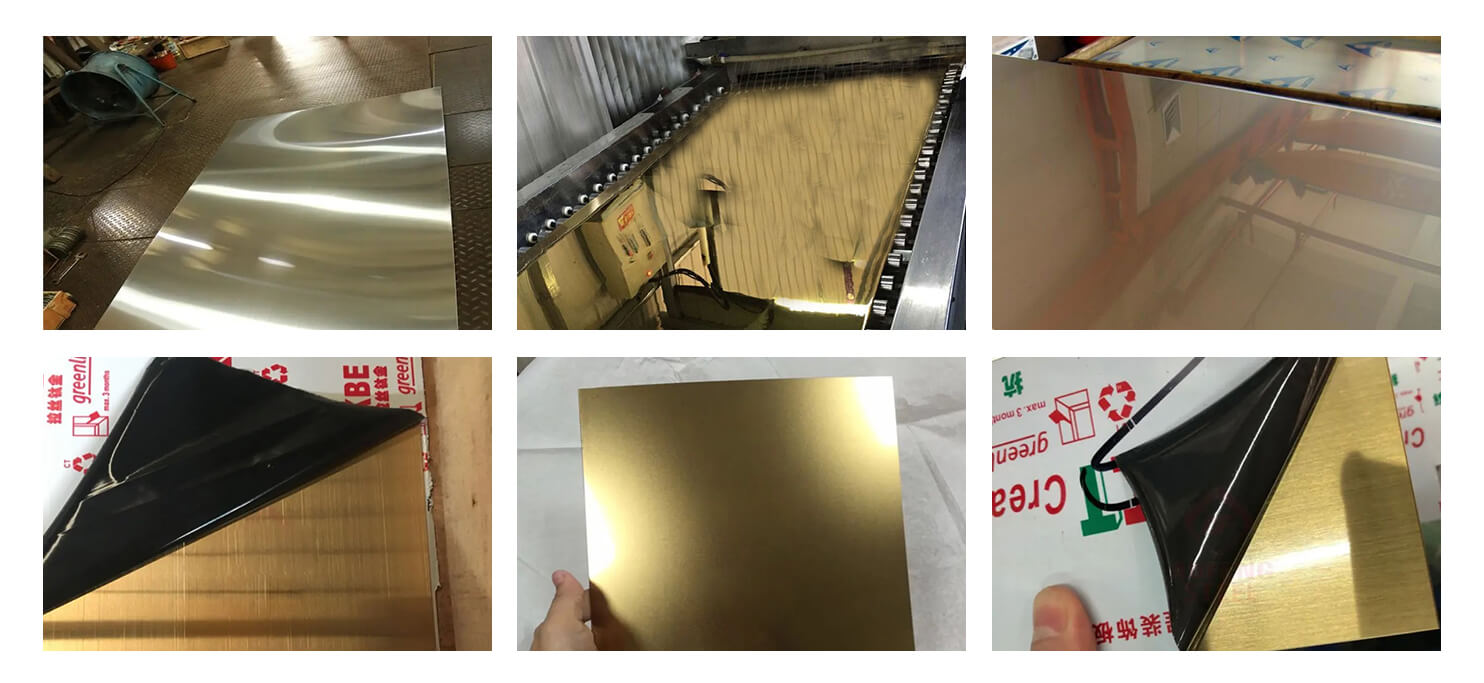

The application of color stainless steel plate is more and more widely. Chinese colored stainless steel not only has the luster and strength unique to the metal, but also has a colorful and long-lasting color. The color stainless steel plate not only maintains the physical, chemical and mechanical properties of the primary color stainless steel, but also has stronger corrosion resistance than the primary color stainless steel.

Extension is introduced

Materials:

The black stainless steel is available in 304 and 316 stainless steel and offers an attractive finish for general (304) and harsh environments (316). The PVD (Physical Vapor Deposition) surface treatment is quote durable, and is actually harder than the stainless steel surface itself. This sounds great, but don't misunderstand. The benefits are a more scratch resistant finish, but it’s not bullet proof, so don't expect the PVD coating to remain unscathed when you take a wire brush to it. It is vastly superior to the black/grey surface treatments on appliances and other material.

Environmental:

PVD coated stainless steel is excellent for outdoor use as it is not affected by UV. It is also excellent as a secondary coating to the stainless steel as chemicals and detergents do not affect the finish.

Bending:

You can bend the stainless without any issues. The PVD coating will not flake, crack, or otherwise show any any defects. We have formed angles from 0 -180 degrees, and have even hemmed black stainless steel. The hem was an open, teardrop hem, and there were no defects in the surface of the metal, and the coloring was consistent.

Welding:

While you can certainly weld black stainless steel, you will not be able to grind and/or polish the weld. The goal is a weld from the inside of a corner, or from the side that is not seen. If that is not possible, aim for a very fine weld with no filler rod or wire. Of course this will mean having parts that are extremely tight fitting. We can do this for you if needed. Let us know about your requirements if needed on the Contact Us page.

For several years now, we have been manufacturing all of our color-coated garden objects from high-quality stainless steel V2A and not from „normal“ steel, aluminum or hot-dip galvanized steel. Although this is not the cheapest option, it guarantees a long service life and brings many advantages that, in our opinion, justify the higher price in several ways.

Type | Color Coating stainless steel sheets |

Thickness | 0.3 mm - 3.0 mm |

Size | 1000*2000mm, 1219*2438mm, 1219*3048mm, customized Max.width 1500mm |

SS Grade | 304,316, 201,430 etc. |

Finish | PVD Color Coating |

Avaible finishes | No.4, Hairline, Mirror, Etching, PVD Color, Embossed, Vibration, Sandblast, Combination, lamination etc. |

Origin | China |

Packing way | PVC+ waterproof paper + strong sea-worthy wooden package |

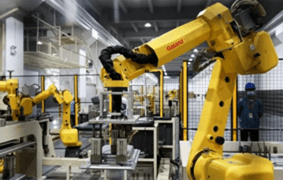

Shandong Kuaima Steel Co., Ltd. has advanced special smelting, investment casting, pipe making and other production equipment. The company has 15 advanced production lines, which can independently produce hot/cold rolled steel, galvalume steel, galvanized steel, prepainted steel and stainless steel coils, strips, plates, plates, pipes, bars and other products. The standing inventory is more than 450,000 tons to meet the customer's demand for delivery time.

We have professional testing equipment. We have our own testing center laboratory to guarantee the quality of our products.

thickness

width

coating quality

chromatic aberration

paint

thickness

hardness

luster

tensile strength

Yield Strength

We are a world-renowned Color coated stainless steel plate exporter, Qatar, Ireland, Portugal,Gambia, Thailand, Ukraine, United Kingdom, Netherlands, South Africa, Spain, Turkey, Italy, Libya, Ro-Fanaticism, Puerto Rico, Azerbaijan, United Arab Emirates, Pakistan, Philippines, Ghana, Slovakia, Germany,Saudi Arabia, Afghanistan, China, Bolivia, Switzerland, Bangladesh, Taiwan, Oman, Egypt, Greece,Norway, Singapore, Bulgaria, Estonia, Belgium, Yemen, Hong Kong, Ecuador, Sri Lanka, Nepal, Belarus,Finland, Gabon, Iran, Canada, Argentina, Lebanon. other countries

Speak to a Steel Expert