Hot Dipped Gi C Shape Steel Channel,Galvanization is the leading method to protect metals from environmental elements that cause corrosion, rust, and the eventual weakening of the steel. Hot-dip galvanizing deposits a thick, robust layer of zinc iron alloys on the surface of a steel item. When exposed to the atmosphere, pure zinc reacts with oxygen to form zinc oxide which further reacts with carbon dioxide to form zinc carbonate. A dull, grey, fairly strong material that stops further corrosion in most circumstances, protecting the steel from the elements.Hot Dipped Gi C Shape Steel Channel is widely used in applications where rust resistance is needed. Hot Dipped Gi C Shape Steel Channel can be welded however, you should exercise caution around the resulting fumes.Hot Dipped Gi C Shape Steel Channel is commonly used in the automotive industry to enhance the corrosion performance of exterior body parts. Hot Dipped Gi C Shape Steel Channel is magnetic.

Corrosion resistance is a prominent advantage of Hot Dipped Gi C Shape Steel Channel. Considering that it will be used in various steel structure facilities, it will inevitably be in contact with the external environment for a long time, or it will be in contact with substances that may cause corrosiveness. The high corrosion resistance ensures that the galvanized channel steel is protected from the external environment and maintains its own structural stability.

Good reliability: the galvanized layer and the steel are metallurgically bonded and become part of the steel surface, so the durability of the coating is more reliable; the toughness of the coating is strong: the galvanized layer forms a special metallurgical structure, which can Withstands mechanical damage during transportation and use; comprehensive protection: every part of the plating can be galvanized, even in depressions, sharp corners and hidden places can be fully protected.

Product name | hot dip galvanized profile C shape steel channel | |||

Standard | AISI,ASTM,DIN,JIS,GB,JIS,SUS,EN,etc. | |||

Material Grade | Q235B,Q345B,Q420B/C,Q460C,SS400/SS540,S235JR/S235J0/S235J2, | |||

Specification | 50*37*4.5 - 400*104*14.5 | |||

Length | 6m, 12m,Large quantity can be customized | |||

Technique | Cold Drawn/Cold pilfered/Cold rolled/Hot rolled/forge-Can be processed again repeatedly | |||

Application | It is mainly used to make structural parts such as car girder, beam, transmission shaft and car chassis parts, which can reduce the weight of the parts.etc. | |||

packing | Waterproof paper, and steel strip packed. | |||

Shandong Kuaima Steel Co., Ltd. has advanced special smelting, investment casting, pipe making and other production equipment. The company has 15 advanced production lines, which can independently produce hot/cold rolled steel, galvanized steel, galvanized steel, prepainted steel and stainless steel coils, Galvanized Channel Steel,strips, plates, plates, pipes, bars and other products. The standing inventory is more than 450,000 tons to meet the customer's demand for delivery time.

| prepainted C-shaped channel steel europe | cold rolled C-shaped channel steel manufacturers |

| prepainted C-shaped channel steel in delhi | cold rolled C-shaped channel steel quotes |

| prepainted C-shaped channel steel in korea | cold rolled C-shaped channel steel suppliers |

| prepainted C-shaped channel steel malaysia | cold rolled C-shaped channel steel wholesaler |

| prepainted C-shaped channel steel prices | cold rolled hot dip C-shaped channel steel |

| prepainted C-shaped channel steel suppliers in mumbai | cold rolled hot dipped C-shaped channel steel |

| prepainted C-shaped channel steel turkey | cold rolled prepainted C-shaped channel steel |

| prepainted C-shaped channel steel wiki | C-shaped channel steel |

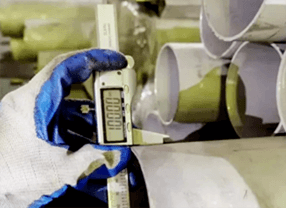

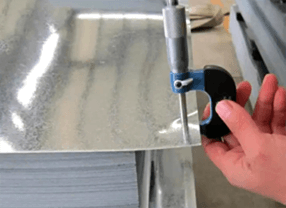

We have professional testing equipment. We have our own testing center laboratory to guarantee the quality of our products.

thickness

width

coating quality

chromatic aberration

paint

thickness

hardness

luster

tensile strength

Yield Strength

We are a world-renowned Galvanized Channel Steel exporter, Qatar, Ireland, Portugal,Gambia, Thailand, Ukraine, United Kingdom, Netherlands, South Africa, Spain, Turkey, Italy, Libya, Ro-Fanaticism, Puerto Rico, Azerbaijan, United Arab Emirates, Pakistan, Philippines, Ghana, Slovakia, Germany,Saudi Arabia, Afghanistan, China, Bolivia, Switzerland, Bangladesh, Taiwan, Oman, Egypt, Greece,Norway, Singapore, Bulgaria, Estonia, Belgium, Yemen, Hong Kong, Ecuador, Sri Lanka, Nepal, Belarus,Finland, Gabon, Iran, Canada, Argentina, Lebanon. other countries.

Speak to a Steel Expert