2023-02-10

A perforated sheet is a metal sheet that’s punched or cut to produce a pattern of holes, slots or shapes for practical or aesthetic purposes. It’s also known as “perforated metal.”

This type of metal sheet includes decorative hole patterns such as circles, squares, triangles, diamonds, hex, slots, bars and so forth. By combining shapes, it is possible to create more complex designs.

The most common methods for cutting into perforated sheets include a punch press, plasma cutter, laser cutter, nibbler machine or a water jet cutter.

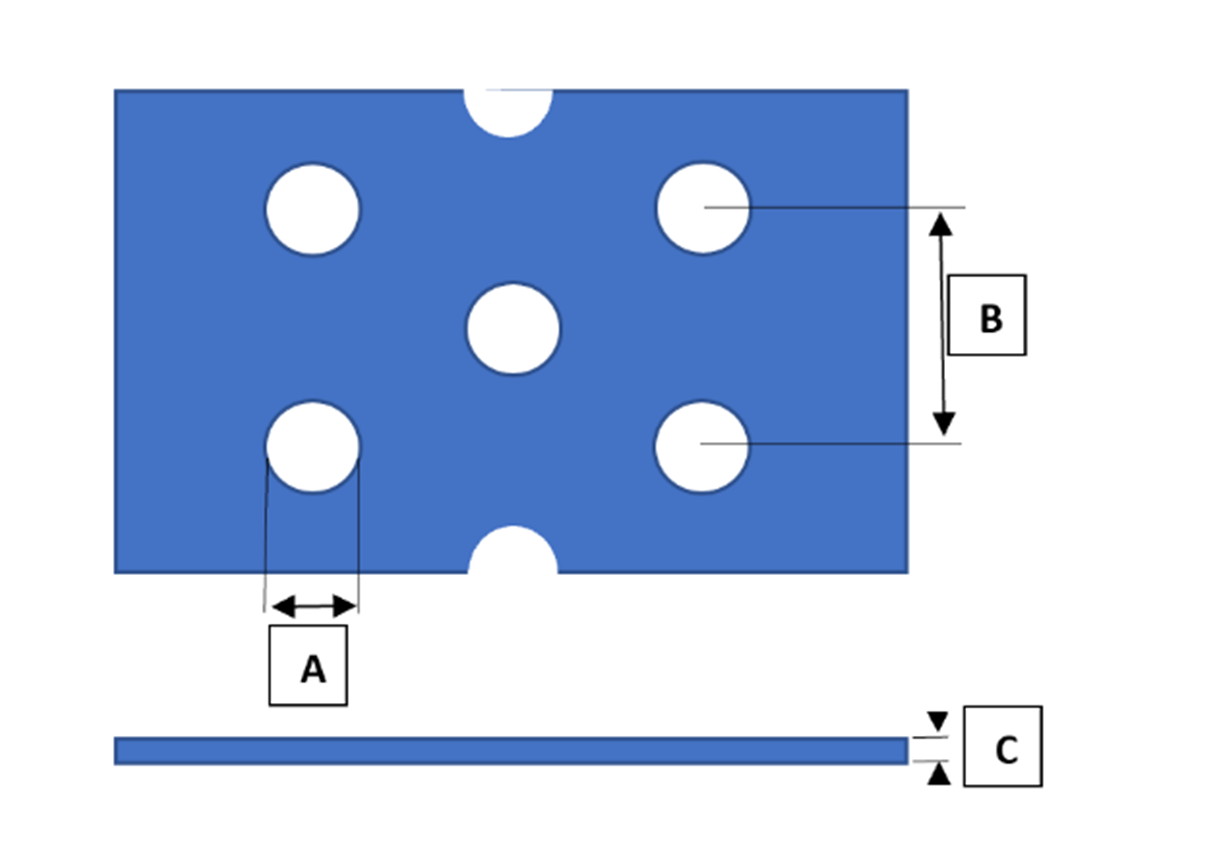

Using common perforated sheet terminology, we’d start by looking at the hole pattern (‘staggered hole”) followed by the hole size (i.e., a circle diameter) [A], the “stagger’ (the distance between holes from center to center) [B] and finally the sheet gauge (or thickness) [C]. You typically measure the dimensions in millimetres.

Example: Staggered Hole 1.000” X 1.250” X 11 Ga. (or 0.125”). This refers to a staggered hole pattern with 1-inch diameter holes spaced 1.25-inches apart on 11-gauge sheet material.

A hole pattern is the arrangement of holes on a sheet in either staggered or straight rows.

In a staggered hole pattern, the direction of the stagger is typically parallel to the short dimension of the sheet. The 60° staggered is the most common pattern. Although other designs are available, 60° staggered is the strongest, most versatile and most economical perforated pattern.

“Gauge” is a British term that refers to sheet thickness. It originated before the advent of the standard metric and standard measurement systems but remains a common term for wire diameter and sheet thickness.

As a rule of thumb, the higher the gauge number, the thinner the metal thickness.

Interestingly, gauge dimensions can vary slightly depending on the material type. “10-gauge” refers to 0.1345” mild steel, 0.1019” aluminum, 0.14062” stainless steel, 0.1382” galvanized steel, 0.1019 brass and 0.134” copper.

In addition to coming in a wide range of materials, patterns and sheet thicknesses, perforated metal sheets are extremely versatile.

The applications are many – some functional, others decorative. These include (but are not limited to) metal guards, filters, vents, screens, diffusers, safety barriers, signage as well as architectural uses.

Why? Its high strength-to-weight ratio.

This is also the reason why perforated metal sheets are the perfect choice for diffusing sound, enhancing acoustic performances and tuning out those unwanted frequencies.

You would also use it to diffuse light, augment lighting environments and create more privacy.