2021-12-27

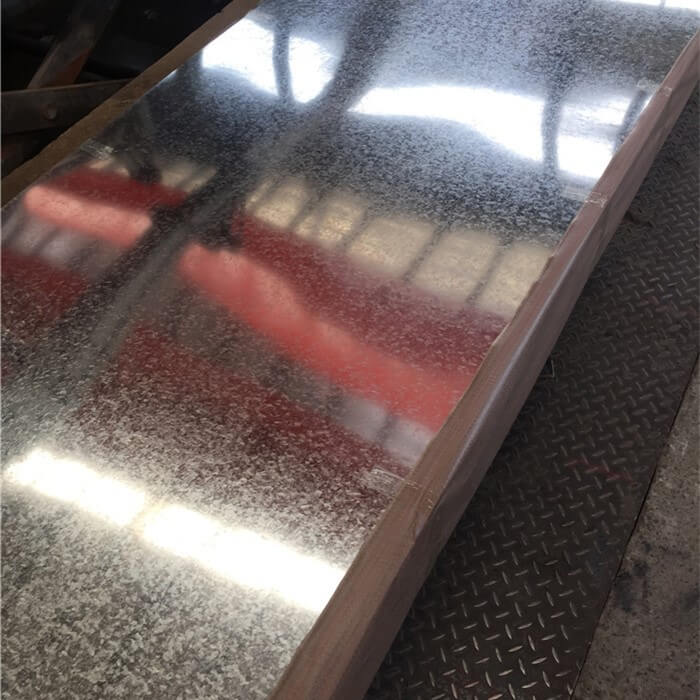

Hot-dip galvanized sheet is a kind of corrosion-resistant galvanized grating product in which the steel grating made by electric welding penetrates into the molten zinc or zinc alloy material to produce a zinc coating on the surface of the stainless steel sheet. Hot-dip galvanizing is now a more common and cost-effective steel anti-corrosion treatment process. Hot-dip galvanizing technology can avoid the corrosion of steel crafts, increase the service life, and save energy consumption. Hot-dip galvanized steel is a resource-saving development prospect.

The corrosion resistance of hot-dip galvanized sheet comes from the standard level of zinc and the standard electrode potential of iron. Therefore, the zinc layer is protected cathodically in the presence of water or damp and cold gas to maintain the steel base, which greatly improves the performance of steel crafts. Validity period. Hot-dip galvanizing, phosphating treatment, thermal spraying hot-dip galvanizing, and hot-dip galvanizing of mechanical equipment are common types of hot-dip galvanizing in industrialization, and hot-dip galvanizing accounts for about 80% of all.

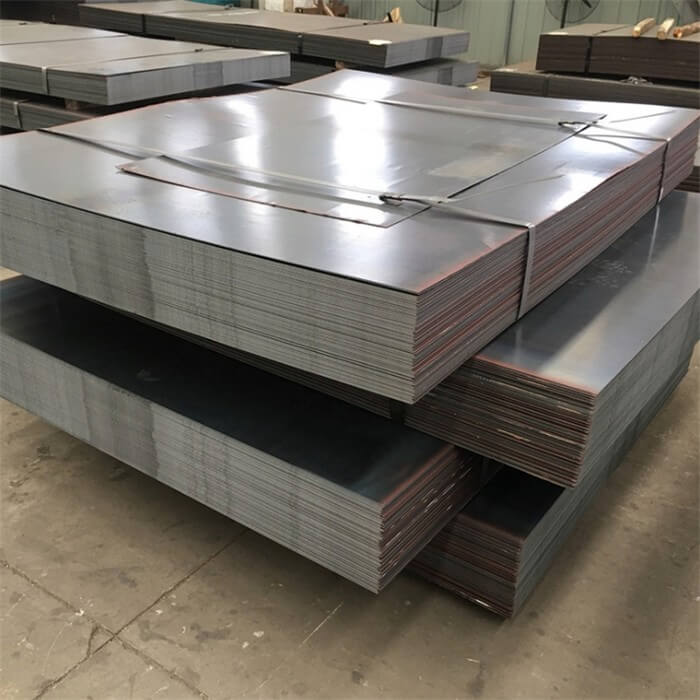

The main purpose of the galvanized sheet: cold-rolled steel sheet penetrates into the molten zinc tank, and its surface is adhered to a cold-rolled steel sheet with a layer of zinc. This type of thick steel plate not only has the function of anti-rust treatment, but also has the function of spraying. In electric welding, spraying, rust prevention, etc., it has stronger adaptability. According to the main purpose, galvanized sheet can be divided into general use, indoor use, engineering building side panels, structural use, corrugated sheet use, pull-shen use and low-alloy sheet use.